"I Like That BONITALL Products Can Accompany Customers Every Day.''Why should I make bathroom products? Because the first thing we do after we wake up every day is to wash in the bathroom. From the moment we walk into the bathroom is the beginning of the day, it will affect our mood and mental attitude of the day. "I Think BONITALL Is Not Only Bringing Products To Society, But Also Become A Century-Old Company."

|

|

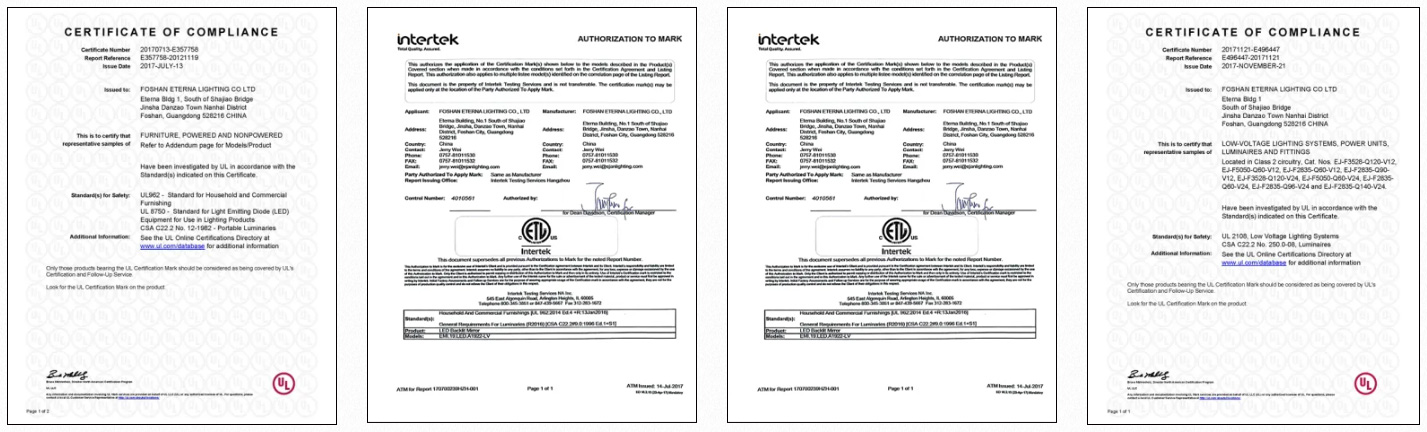

Bonitall always focus on the product quality and fine management of workshop, so that we can pass the test from different inspection organizations and obtain different certifications, include SO14001, ISO9001, ETL, CE, FSC, SGCC, SAA etc.

|

|

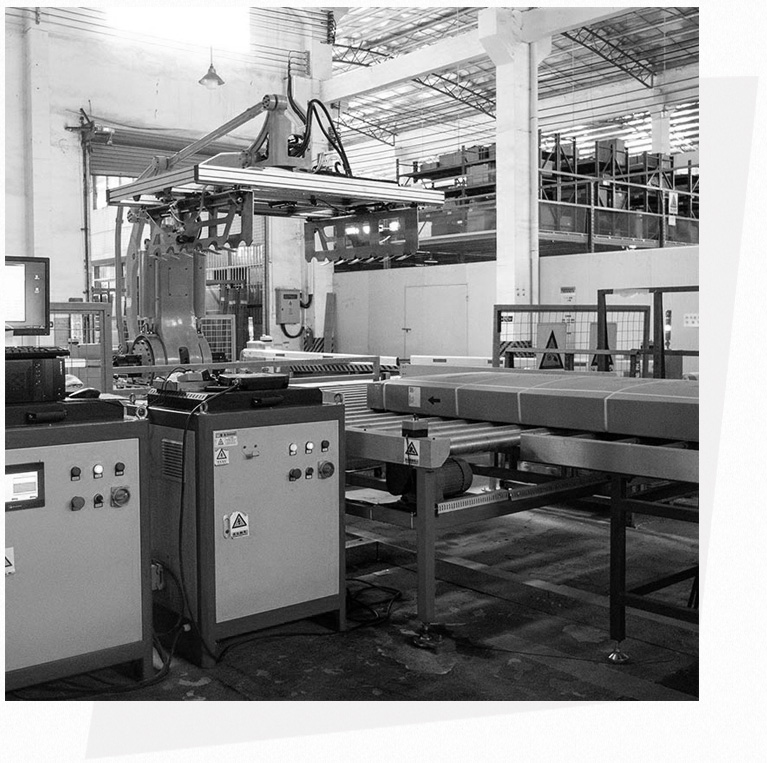

LED lamp production process process refers to a series of process steps required in the process of producing LED lamps. The process includes the following main steps: 1.LED chip preparation: Preparation of LED chip is the first step in LED lamp production, which mainly includes thin film growth, wafer preparation, wafer separation and other steps. These are the main steps of the LED lamp production process, and each step needs to be strictly controlled to ensure the production of high-quality LED lamps. |

|

The production process of the shower room starts from the design stage. At this stage, the designer will communicate with the customer to understand their needs and requirements. At the same time, they also have to take into account the space size, style and decoration factors. Designers need to ensure that the shower room is coordinated with the entire bathroom design and meets the customer's budget and quality requirements. After the design scheme is determined, the material procurement stage follows. Glass processing is the important link of shower room production. Glass is usually the main material in the shower room, so special processing is needed. This includes the cutting, polishing, drilling, and tempering of the glass. These processing steps can ensure the firmness and safety of the glass. Assembly is another important link in the production of shower rooms. Assembly |

|

|

Solid wood bathroom cabinet is very strict on the material selection. The wood must be dried for at least two years so that the cells inside the wood can be completely dead, keeping the moisture content of the wood to a minimum. First-class equipment and technology to ensure the quality of the solid wood bathroom cabinet, part of the process is to use hand cutting and hand carving and grinding. There are a lot of patterns and lines above the high-end solid wood bathroom cabinet are from the senior master hand carving, and some even have a large totem sculpture independent of the bathroom cabinet. Solid wood bathroom cabinet needs to pass the wood material opening material, assembly, closed, many times grinding, spray paint and other more than 40 processes and become. Behind the excellent quality of the bathroom ark, condensed the painstaking effort of the bathroom person. Solid wood bathroom cabinet meticulous and comprehensive pre-sale door measurement, the sale of door-to-door installation, after-sales regular return visit, good after-sales service can remove the consumer worries at home. |

|

With 4 production bases total 150,000M2 workshops and over 900 workers.It takes bathroom vanity, led bathroom mirror and shower door as

its flagship and drives the development of related industries, including faucets, showers, toilet etc., forming a diversified industrial pattern. |